Quick Look

| Density(g/cm³) | Tensile Strength | Yield Strength | Elongation at Break | Thermal Conductivity |

|---|---|---|---|---|

| 2.7 | 300MPa | 180MPa | 8.00% | 147 |

About the Material

Advantages:

High Strength-to-Weight Ratio: AlSi10Mg provides a lightweight yet strong material, ideal for aerospace and automotive parts.

Good Thermal Conductivity: The material has excellent thermal conductivity, making it suitable for heat exchangers and thermal management components.

Corrosion Resistance: AlSi10Mg is naturally resistant to corrosion, making it suitable for outdoor and industrial applications.

Design Flexibility: SLM technology enables the creation of complex and optimized geometries, reducing material usage and weight.

Limitations:

Residual Stress: The SLM process can create residual stresses in parts, which may require heat treatment to relieve.

Surface Finish: Parts produced with SLM may require post-processing to achieve a smooth surface finish.

Limited Build Size: The maximum part size is limited by the build volume of the SLM machine, which may restrict certain applications.

Chemical Composition Table for Aluminum (AlSi10Mg)

| Element | Composition (%) |

| Aluminum (Al) | Balance |

| Silicon (Si) | 9-11 |

| Magnesium (Mg) | 0.25-0.45 |

| Iron (Fe) | ≤ 0.55 |

| Others | ≤ 0.15 |

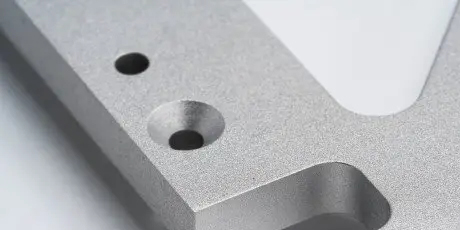

Mechanical Machining Properties Table for Aluminum (AlSi10Mg)

| Property | Value |

| Machinability Rating | Good |

| Cutting Speed (m/min) | 200-300 |

| Tool Wear Resistance | High |

| Coolant Requirement | Recommended |

| Surface Finish Quality | High |

Design Parameters Table for SLM Printing with Aluminum (AlSi10Mg)

| Maximum Bulid Size(mm) | Minimum Wall Thickness | Minimum Drill Size | Minimum Assembly Gap | Tolerance |

| 400*300*400 | 1mm | 1mm | 0.15mm | ±0.2% *Length(lower limit of ±0.2 mm) |

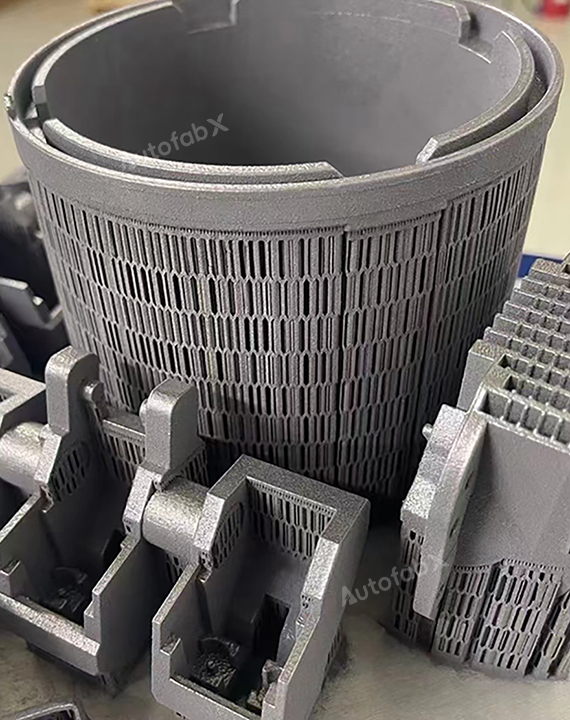

Industry Applications and Case Studies for SLM Printing with Aluminum (AlSi10Mg)

Aerospace Industry:

Application: Production of lightweight structural components.

Case Study: An aerospace company used AlSi10Mg to produce bracket components, reducing weight while maintaining strength requirements.

Automotive Industry:

Application: Manufacturing of lightweight parts for high-performance vehicles.

Case Study: An automotive manufacturer used AlSi10Mg to produce engine components, achieving weight reduction and improved fuel efficiency.

Heat Exchangers:

Application: Production of heat exchangers and thermal management components.

Case Study: A heat exchanger manufacturer used AlSi10Mg to produce complex heat exchanger designs, benefiting from the material's thermal conductivity.

Frequently Asked Questions (FAQs) about SLM Printing with Aluminum (AlSi10Mg)

What are the benefits of using AlSi10Mg in 3D printing?

AlSi10Mg offers a high strength-to-weight ratio, good thermal conductivity, and corrosion resistance, making it suitable for aerospace, automotive, and thermal management applications.

Is AlSi10Mg suitable for functional parts?

Yes, AlSi10Mg is ideal for functional parts that require lightweight strength, durability, and thermal conductivity.

What industries benefit from SLM printing with AlSi10Mg?

Industries such as aerospace, automotive, and heat exchanger manufacturing benefit from the strength, weight reduction, and thermal properties of AlSi10Mg.

How accurate is SLM printing with AlSi10Mg?

SLM printing with AlSi10Mg can achieve tolerances of ±0.1 mm, suitable for most functional and high-precision applications.

What post-processing is required for AlSi10Mg-printed parts?

Post-processing may include heat treatment, machining, and surface finishing to improve mechanical properties and appearance.

Can AlSi10Mg be used in high-temperature environments?

AlSi10Mg has a maximum operating temperature of 200°C, making it suitable for moderate-temperature applications.

How strong are AlSi10Mg-printed parts?

AlSi10Mg-printed parts are strong and lightweight, with good mechanical properties, making them suitable for structural and load-bearing applications.

Finishing Options

Parts Made by AutofabX