Precision on Demand, Affordable by Global Connection

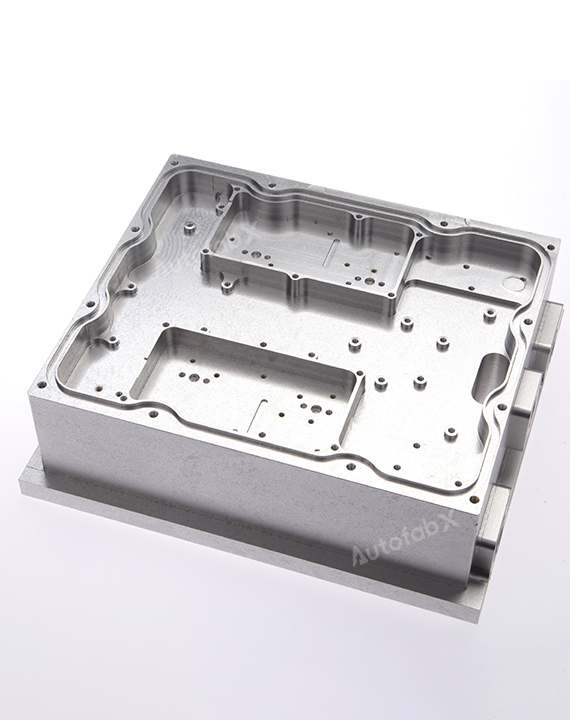

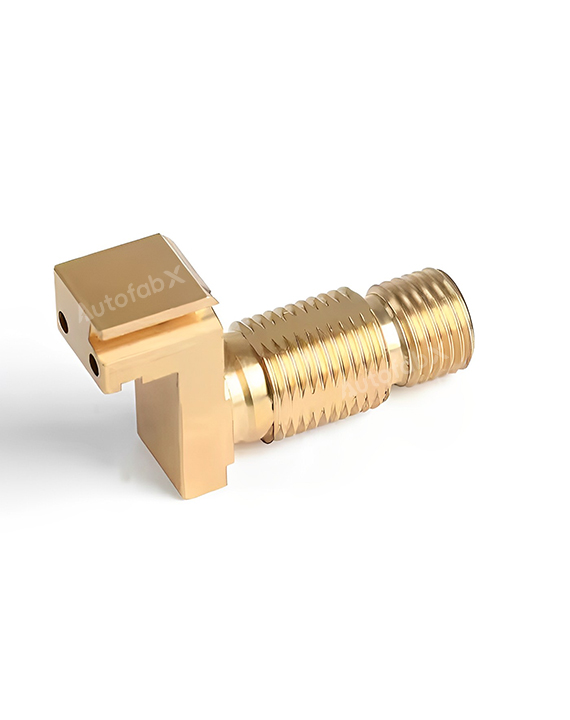

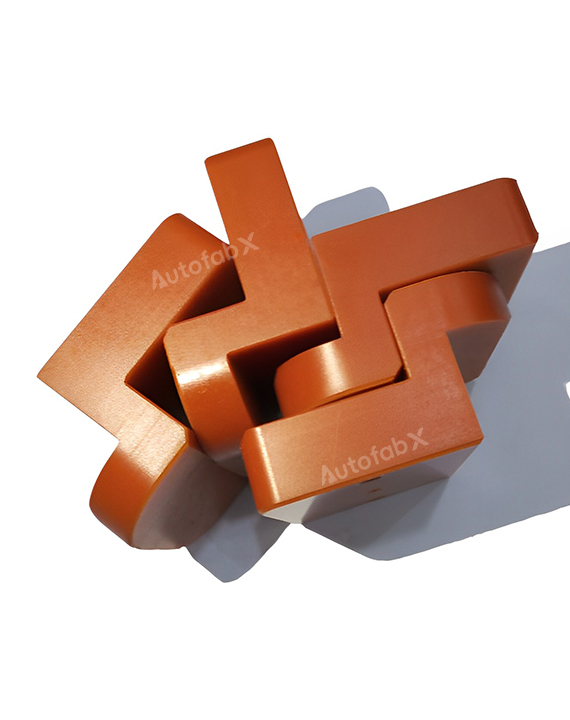

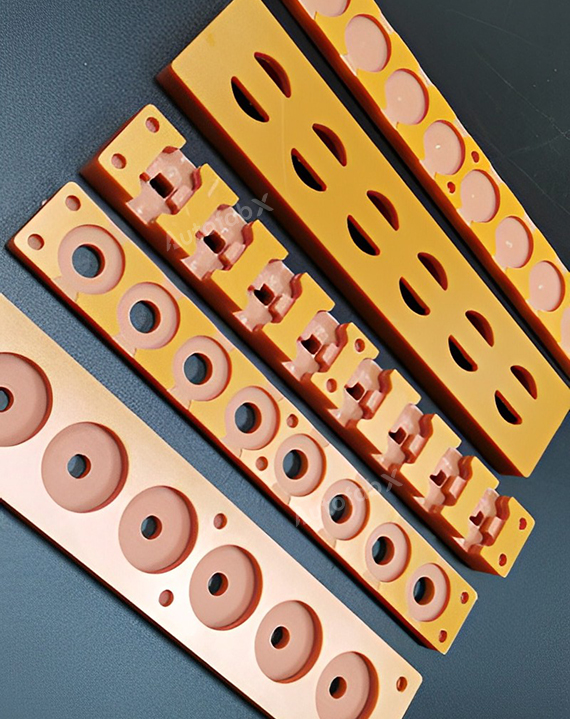

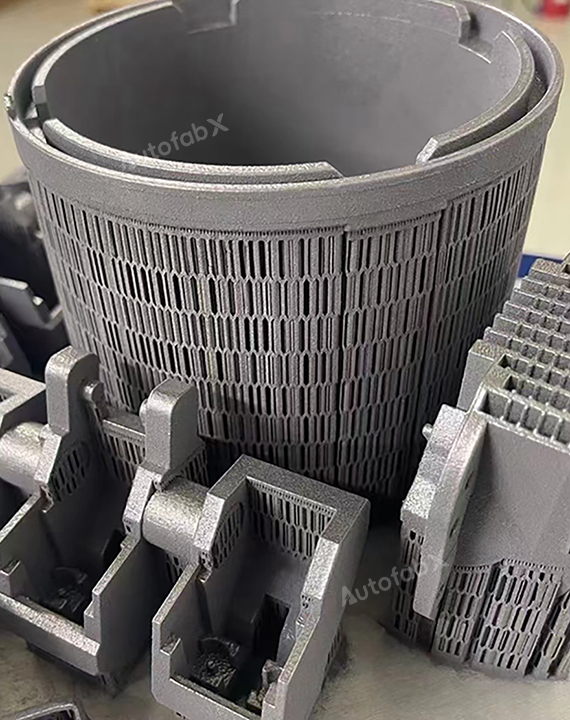

AutofabX specializes in providing product prototyping and small-batch manufacturing services for businesses. Originally one of the top three 3D printing and CNC factories in Asia, the company transformed in 2024 into a global manufacturing platform empowered by digital technologies. Leveraging our three self-operated factories in China and a network of hundreds of carefully selected supply chain partners worldwide, AutofabX delivers comprehensive manufacturing services, including 3D printing, CNC machining, casting, MIM, and injection molding, to over 40,000 enterprise customers.

40000

Customers

900+

Employees

3

self-owned factories

120

Certified partner factories

170+

Countries Shipped

>95%

On-time delivery

<0.3%

Quality Complaint Rate

10 Million

Parts Produced/Year

Our Mission

Faster, High-Quality and Cost-Effective

To redefine the global manufacturing supply chain through digitalization, offering customers advanced technology, high-quality services, cost-effective solutions, and a one-stop shop for all their manufacturing needs.

Benefits of Working with Us

Swift Support and Quick Validation

We offer swift support for process inquiries, rapid prototyping validation, and quick consultation on optimal process packages for various production volumes. This ensures efficient and cost-effective solutions tailored to our customers' needs.

Learn More about AutofabX Quality Inspections

Cost Leadership and Efficiency

From prototyping to small and large-scale production, we ensure leading manufacturing cost advantages through optimal process selection. For heavy metal parts, our superior international logistics capabilities minimize shipping costs. Additionally, our software for quoting and production planning reduces service and communication costs.

Cost Reduction

in building a hardware project

50%

Time Saved

for Create, Debug and Evaluate...

30%

Data Security and Privacy

As a U.S.-based company, we ensure that user data is stored in secure American and European cloud services. Design data is only shared with factories that have signed an NDA, and users have full control over the retention period of their data.

What our customers say

Jonason

Product Development Manager at a renowned automotive company

“AutofabX has been instrumental in our automotive product development process. Their machining capabilities consistently deliver high-precision parts that meet our exact specifications. They understand the unique demands of the automotive industry, and their proactive problem-solving ensures seamless project execution. Partnering with AutofabX has significantly enhanced our product quality and accelerated our time to market.”

Tyrese

Procurement Manager at a leading electrical company

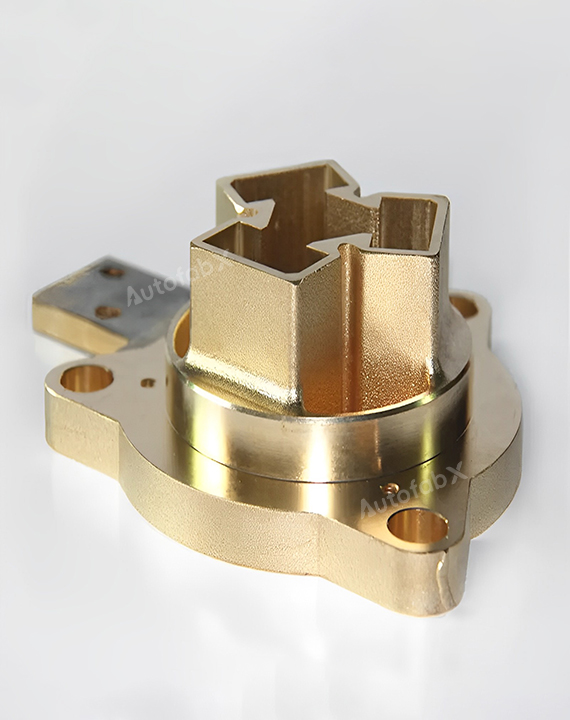

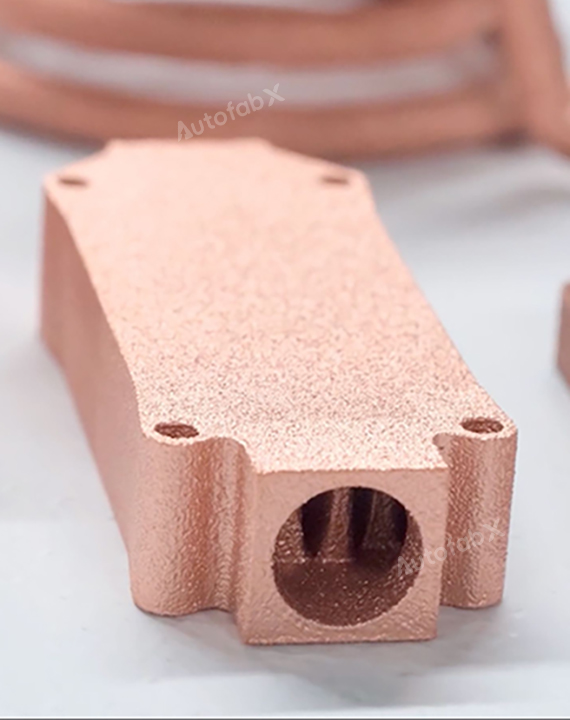

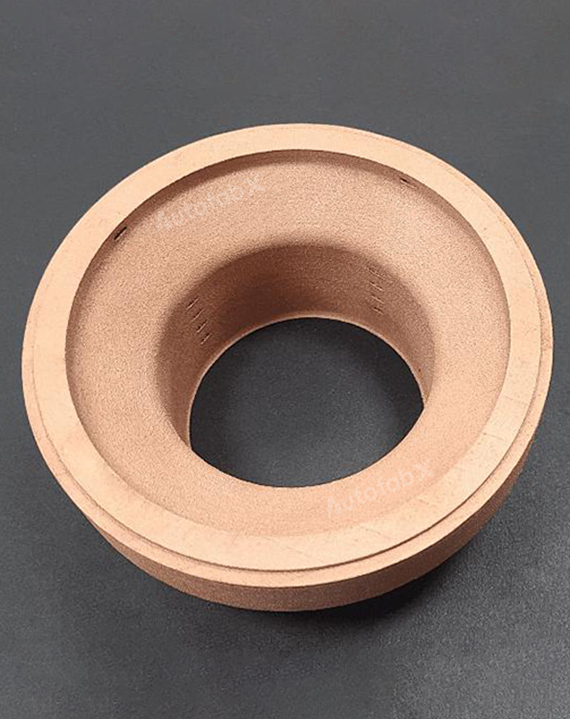

“Choosing AutofabX for Investment Casting was a strategic decision for our electrical company. Their craftsmanship and attention to detail are exceptional, producing complex metal components that consistently exceed our expectations. Their collaborative approach and tailored solutions have streamlined our procurement processes and enhanced our supply chain resilience. AutofabX's unwavering commitment to quality and reliability has made them an invaluable partner in our operations.”

Nicole

Senior Design Engineer at a top-tier consumer electronics company

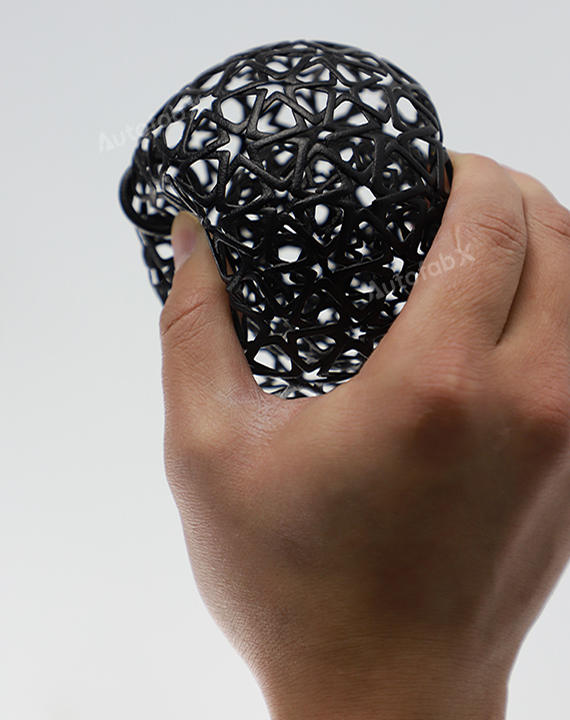

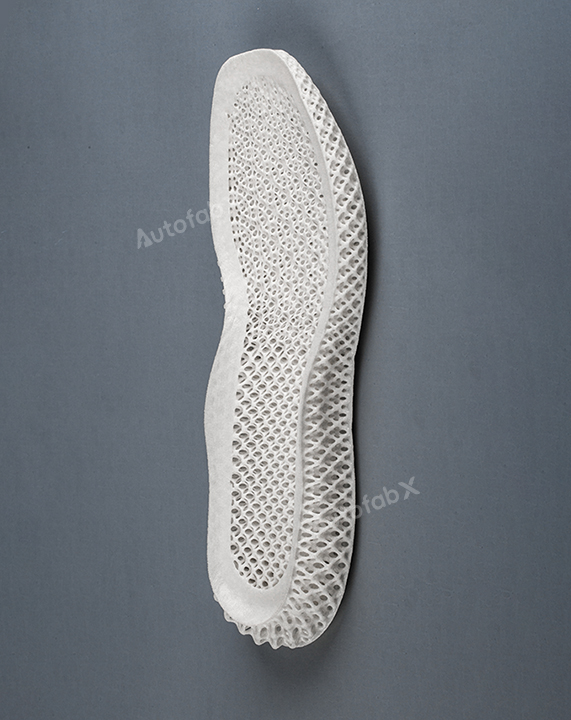

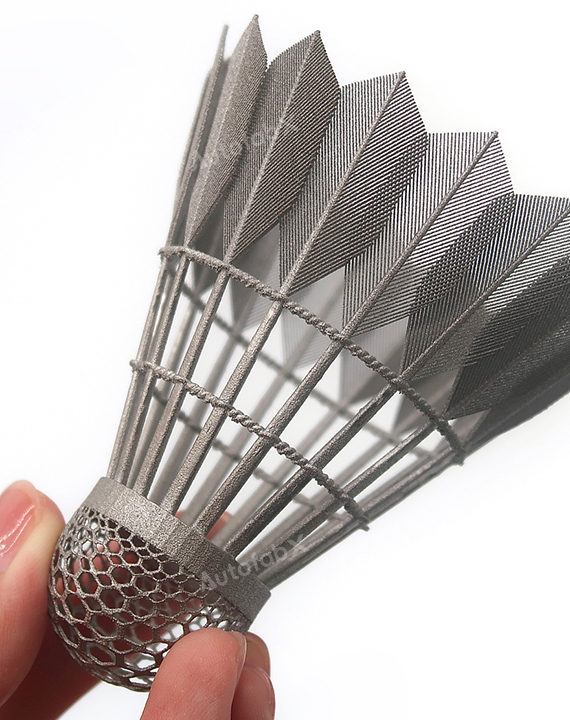

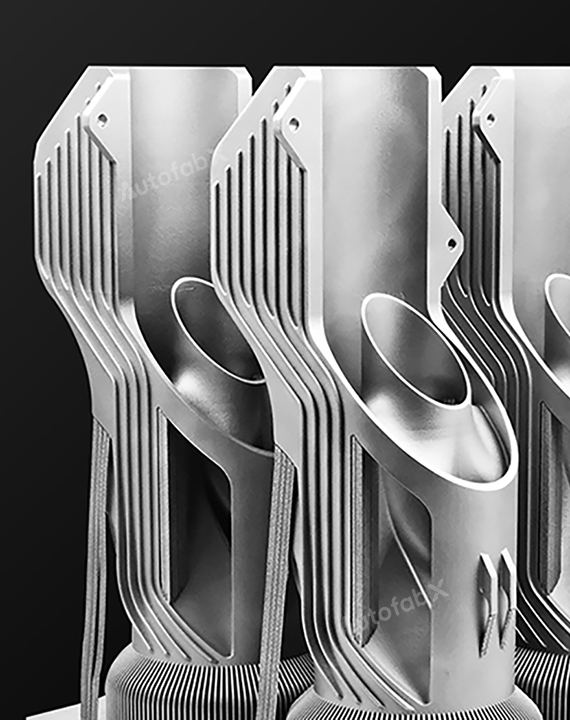

”We rely on AutofabX's advanced 3D printing capabilities to swiftly iterate and validate our design concepts in the consumer electronics industry. Their expertise in handling intricate geometries and diverse materials has been pivotal in bringing our innovative ideas to life. Their adaptability and dedication to delivering top-notch quality have established them as a trusted ally in our product development journey.“

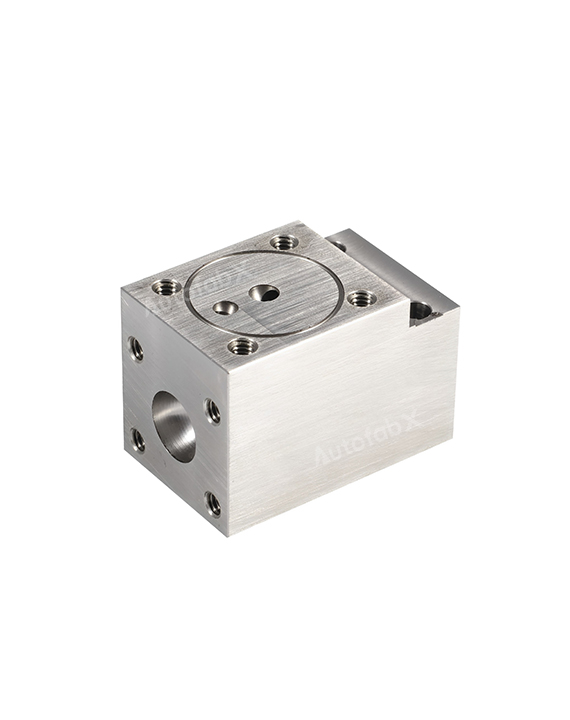

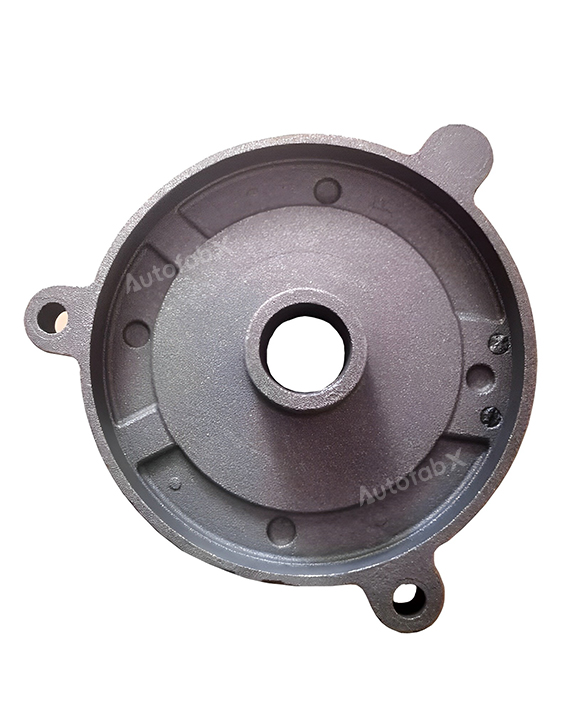

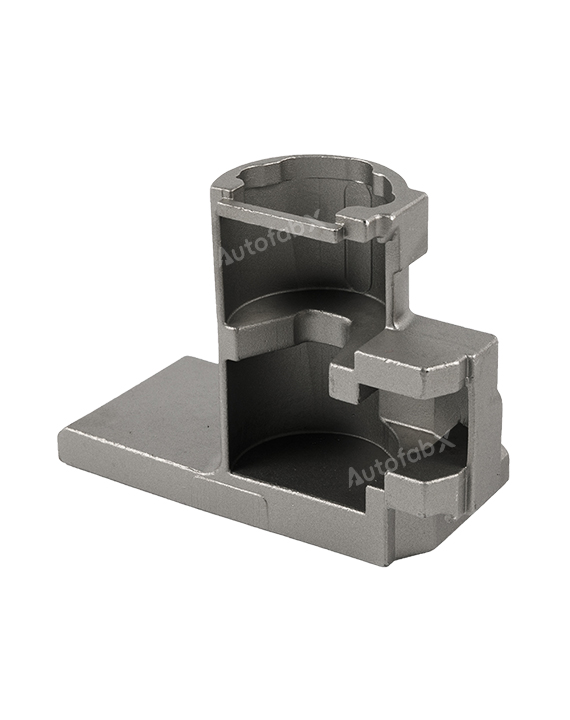

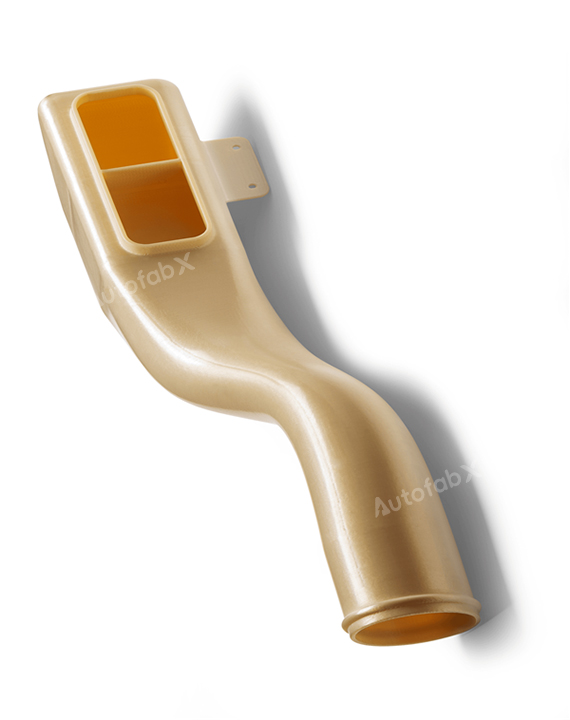

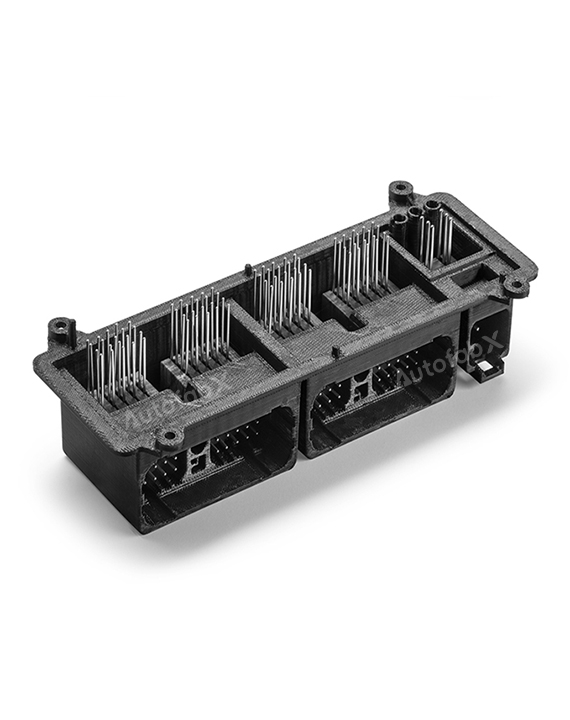

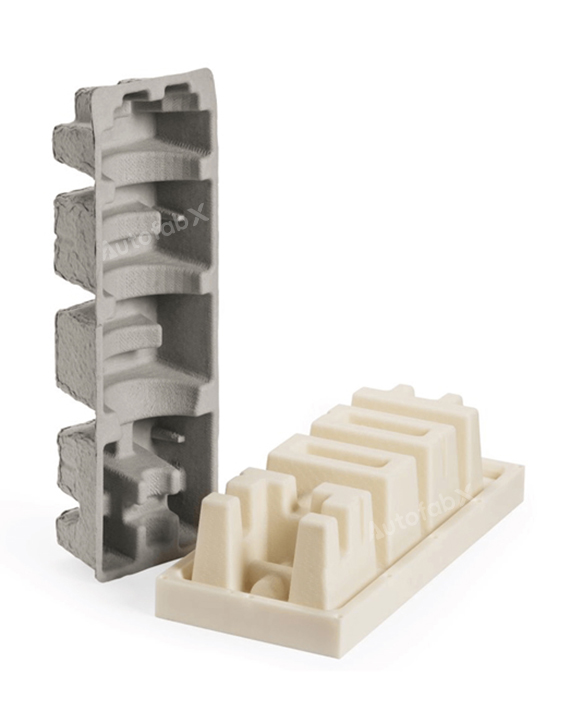

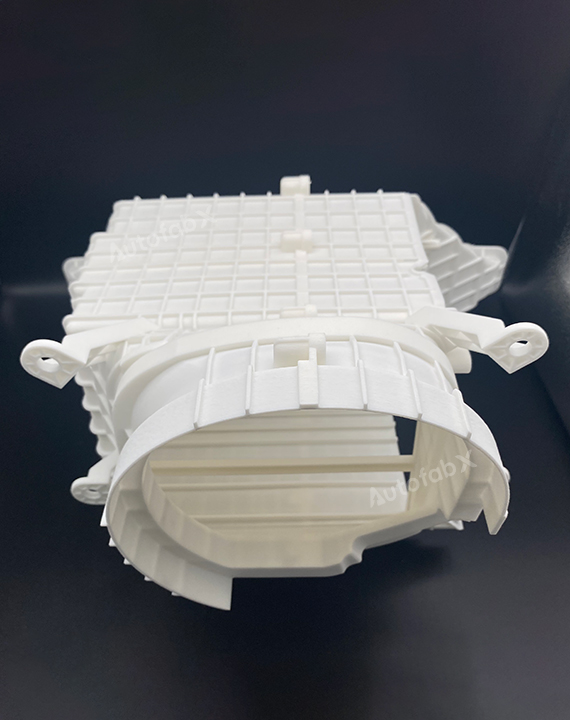

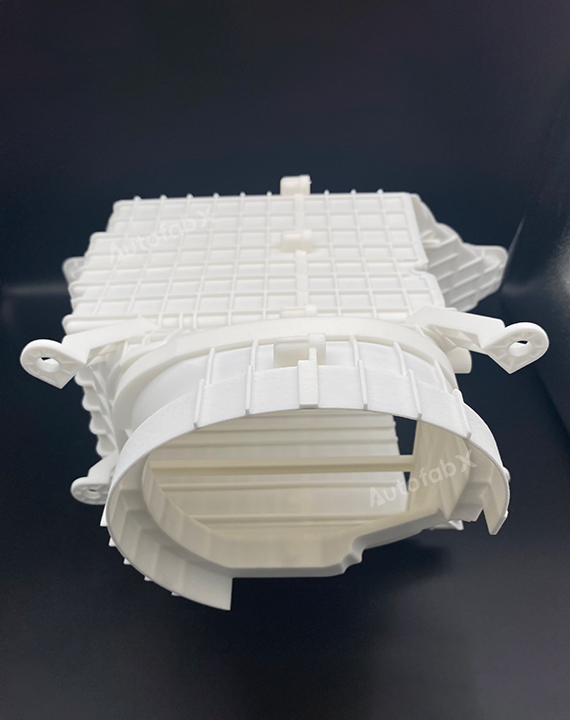

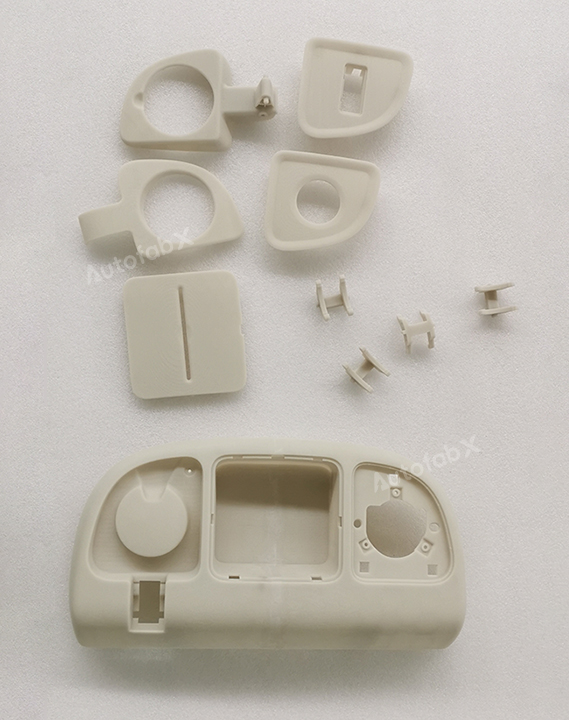

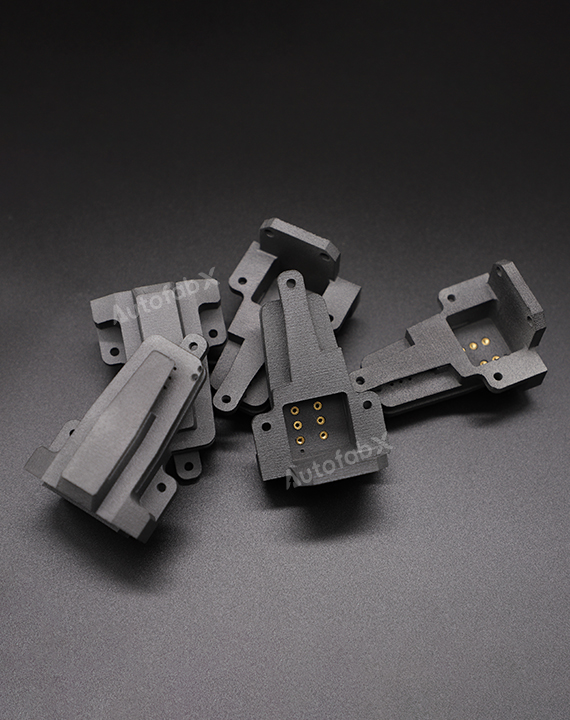

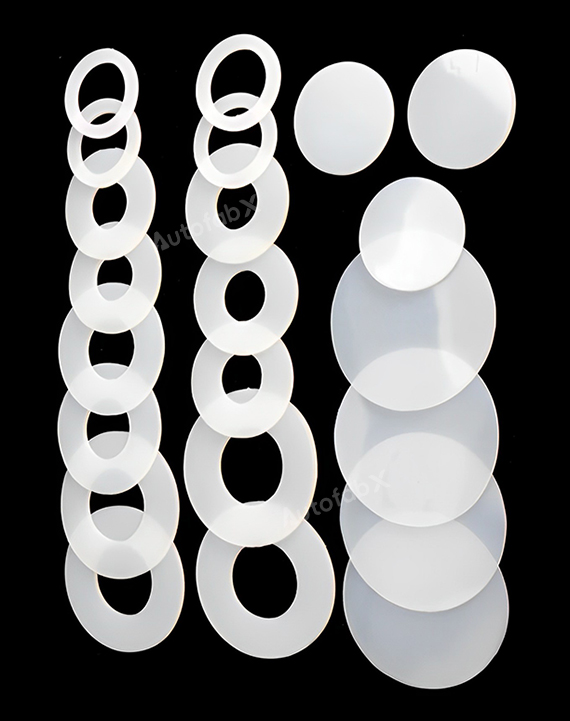

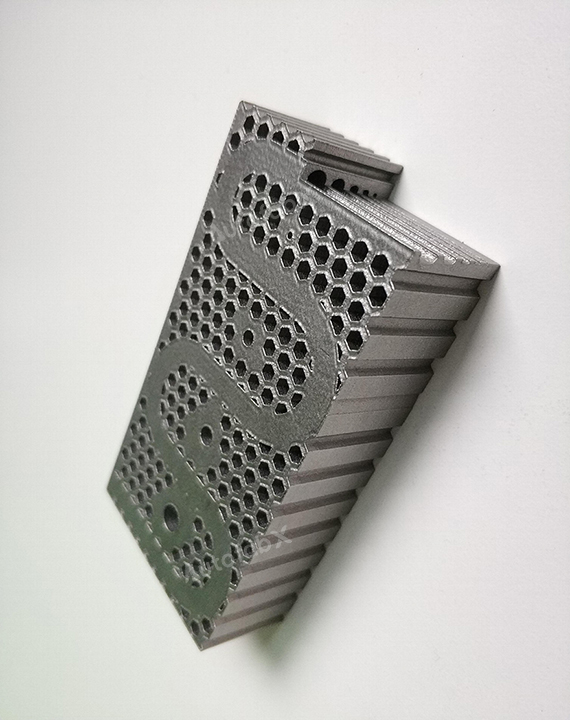

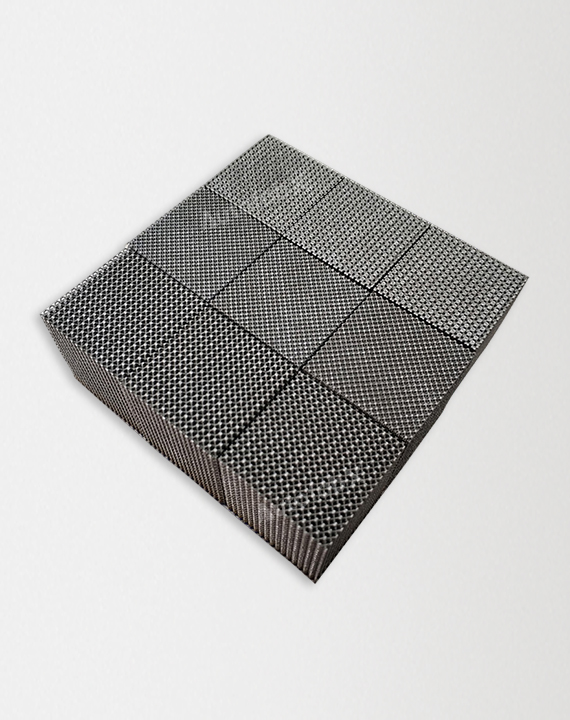

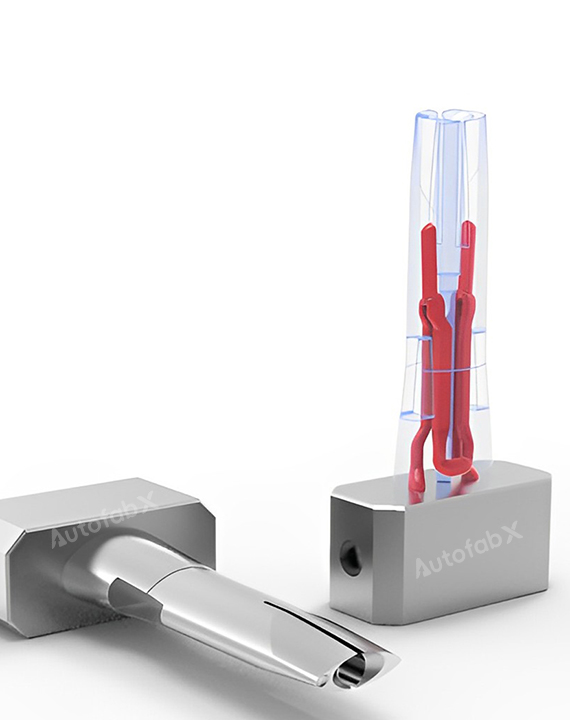

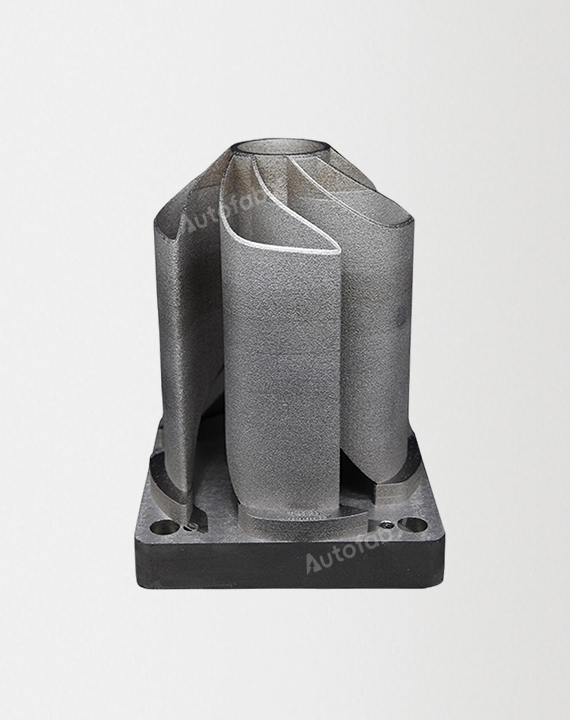

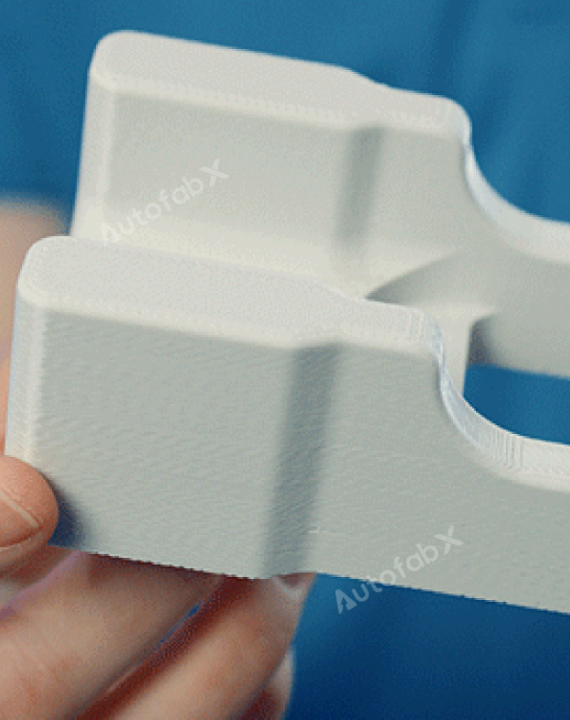

Parts Made by AutofabX