Quick Look

| Density | Tensile Strength | Yield Strength | Elongation at Break | Hardness |

|---|---|---|---|---|

| 7.7-7.8 g/cm³ | 900-1300 MPa | 650-1100 MPa | 10-20% | 30-40 HRC |

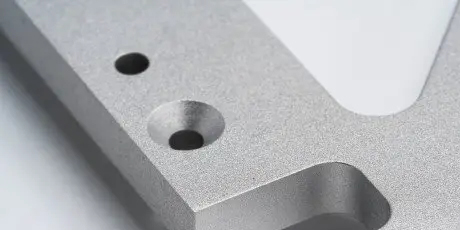

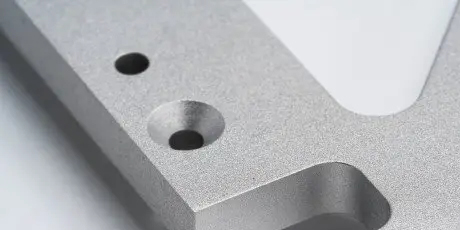

About the Material

Advantages:

Complex Geometries: Binder Jetting can produce parts with intricate geometries, including internal channels and lattice structures.

Cost-Effective for Batch Production: Binder Jetting is economical for producing multiple parts simultaneously, making it suitable for medium to high-volume production.

No Support Structures: The powder bed provides natural support, allowing for the creation of complex features without additional supports.

Heat Treatment Flexibility: Stainless Steel 17-4PH can be heat treated to achieve specific mechanical properties, offering versatility for different applications.

Limitations:

Porosity: Parts produced via Binder Jetting may have higher porosity compared to parts made with other metal additive processes, requiring additional post-processing.

Post-Processing Requirements: Sintering or infiltration is needed to achieve full density, which can add complexity to the production process.

Surface Finish: The as-printed surface finish may require additional post-processing, such as polishing or machining, to meet desired specifications.

Chemical Composition Table for Stainless Steel 17-4PH

| Element | Typical Composition (%) |

| Iron (Fe) | Balance |

| Chromium (Cr) | 15-17.5 |

| Nickel (Ni) | 3-5 |

| Copper (Cu) | 3-5 |

| Niobium (Nb) + Tantalum (Ta) | 0.15-0.45 |

| Carbon (C) | ≤ 0.07 |

Mechanical Machining Properties Table for Stainless Steel 17-4PH

| Property | Value |

| Machinability Rating | Moderate |

| Cutting Speed (m/min) | 20-40 |

| Tool Wear Resistance | Moderate |

| Coolant Requirement | Essential |

| Surface Finish Quality | Moderate |

Design Parameters Table for Binder Jetting with Stainless Steel 17-4PH

| Design Aspect | Value |

| Minimum Wall Thickness | 1.5 mm |

| Minimum End Mill Size | 2.0 mm |

| Minimum Drill Size | 1.5 mm |

| Maximum Part Size | 300 mm x 300 mm x 200 mm |

| Undercuts | Allowed |

| Radii : Depth | Minimum 1.5 mm radius for depth features |

| Tolerance | ±0.3 mm |

| Maximum Temperature | 315°C |

Industry Applications and Case Studies for Binder Jetting with Stainless Steel 17-4PH

Aerospace Industry:

Application: Production of lightweight, high-strength components.

Case Study: An aerospace company used Binder Jetting to produce stainless steel brackets, reducing weight while maintaining strength and durability for flight components.

Medical Industry:

Application: Production of surgical instruments and medical devices.

Case Study: A medical device manufacturer utilized Binder Jetting to create custom surgical tools, reducing production costs and enabling rapid iteration.

Automotive Industry:

Application: Manufacturing of exhaust components and structural parts.

Case Study: An automotive manufacturer used Binder Jetting to produce stainless steel exhaust manifolds, optimizing weight and corrosion resistance.

Frequently Asked Questions (FAQs) about Binder Jetting with Stainless Steel 17-4PH

What materials can be used in Binder Jetting?

Binder Jetting can use a variety of materials, including metals, ceramics, and sand. Stainless Steel 17-4PH is one of the commonly used metal powders.

Is Binder Jetting suitable for functional parts?

Yes, Binder Jetting can produce functional parts, but post-processing such as sintering or infiltration is often required to achieve the desired mechanical properties.

What industries benefit from Binder Jetting with Stainless Steel 17-4PH?

Industries such as aerospace, medical, and automotive benefit from the strength, corrosion resistance, and cost-effectiveness of Stainless Steel 17-4PH parts produced via Binder Jetting.

How accurate is Binder Jetting with Stainless Steel 17-4PH?

Binder Jetting can achieve tolerances of ±0.3 mm, which is suitable for many functional applications, but additional post-processing may be needed for higher precision.

What post-processing is required for Binder Jetting parts?

Post-processing may include curing, sintering, infiltration, or surface finishing to achieve the desired properties and appearance.

Can Binder Jetting produce complex geometries?

Yes, Binder Jetting is well-suited for producing complex geometries, including internal features and lattice structures, without the need for support structures.

How strong are parts made with Binder Jetting and Stainless Steel 17-4PH?

Parts made with Stainless Steel 17-4PH are strong and corrosion-resistant, making them suitable for demanding environments. Post-processing can further enhance their mechanical properties.

Finishing Options

Parts Made by AutofabX