Quick Look

| Alloy Number | Density(g/cm3 ) | Rockwell Hardness | Tensile Strength(MPa) | Elongation(%) |

|---|---|---|---|---|

| MIM-2200(Sintered) | 7.65 | 45HRB | 290 | 40 |

| MIM-2700(Sintered) | 7.65 | 69HRB | 440 | 26 |

| MIM-4605(Sintered) | 7.62 | 62HRB | 415 | 15 |

| MIM-4605(Quenching、Tempering) | 7.62 | 48HRC | 1655 | 2 |

About the Material

Advantages:

High Strength: MIM iron base alloys provide high tensile and yield strength, making them suitable for demanding applications.

Complex Shape Capabilities: The ability to produce intricate geometries with tight tolerances is a significant advantage of MIM iron base alloys.

Good Corrosion Resistance: Certain iron base alloys, such as 316L stainless steel, offer excellent resistance to corrosion, making them ideal for harsh environments.

Cost Efficiency in Mass Production: The MIM process is cost-effective for producing large quantities of parts, reducing material waste and production costs.

Consistent Quality: The MIM process ensures high repeatability and consistent part quality, which is essential for precision-critical industries.

Versatility: MIM iron base alloys are suitable for a wide range of industries, including automotive, aerospace, medical, and consumer electronics.

Limitations:

High Initial Tooling Cost: The initial investment for tooling and mold creation is high, making MIM less suitable for low-volume production runs.

Limited Part Size: MIM is generally limited to producing small to medium-sized parts, with weight typically below 100 grams.

Binder Removal Complexity: The debinding process can be time-consuming and requires careful control to avoid defects.

Material Limitations: Not all iron-based materials are suitable for MIM, and the selection of materials is more restricted compared to traditional metalworking methods.

Porosity: Some MIM parts may have residual porosity, which can affect mechanical properties and may require additional processing to achieve full density.

Chemical Properties Table

Alloy Type | Carbon (C) | Chromium (Cr) | Nickel (Ni) | Molybdenum (Mo) | Manganese (Mn) | Silicon (Si) | Other Elements |

Fe-2Ni | 0.1-0.5% | — | 1.5-2.5% | — | 0.5-1.5% | 0.5% max | Phosphorus (P), Sulfur (S) |

Fe-8Ni | 0.1-0.5% | — | 7-9% | — | 0.5-1.5% | 0.5% max | Phosphorus (P), Sulfur (S) |

Fe-Cr | 0.1-0.3% | 11-13% | — | — | 1% max | 1% max | Phosphorus (P), Sulfur (S) |

Machining Properties Table

Alloy Type | Machinability Rating | Cutting Speed (m/min) | Tool Wear Resistance | Coolant Requirement | Hardness (HRC) | Surface Finish Quality |

Fe-2Ni | High | 50-80 | Moderate | Optional | 20-30 | Fair |

Fe-8Ni | High | 45-75 | Moderate | Optional | 25-35 | Fair |

Fe-Cr | Moderate | 35-55 | Good | Required | 30-40 | Good |

Metal Injection Molding Iron Base Alloys Design Parameters

| Maximum Bulid Size (mm) | Minimum Wall Thickness (mm) | Minimum Assembly Gap (mm) | Tolerance (mm) | Minimum End Mill Size (mm) | Minimum Drill Size (mm) |

| 200x100x100 | 1 | 0.1 | 0.1 | / | / |

Industry Applications and Case Studies for MIM Iron Base Alloys:

Automotive Industry:

Application: Production of components such as gears, camshafts, and turbocharger parts.

Case Study: A leading automotive manufacturer used MIM to produce high-precision gears, resulting in reduced production time and material costs while maintaining the durability needed for high-performance vehicles.

Medical Devices:

Application: Manufacturing of surgical instruments, orthodontic brackets, and implantable devices.

Case Study: A medical device company utilized MIM iron base alloys to produce minimally invasive surgical tools, achieving high precision, biocompatibility, and cost-effective production for large quantities.

Consumer Electronics:

Application: Fabrication of connectors, structural components, and hinges for electronic devices.

Case Study: An electronics brand employed MIM to manufacture small, intricate components for smartphones, enabling a sleek design while ensuring strength and durability.

Aerospace Industry:

Application: Production of lightweight yet strong parts used in aircraft systems, such as brackets and fasteners.

Case Study: An aerospace supplier used MIM iron base alloys to create high-strength components for aircraft engines, reducing weight and improving fuel efficiency.

Firearms and Defense:

Application: Manufacturing of firearm components, including trigger mechanisms and hammers.

Case Study: A firearms manufacturer used MIM iron base alloys to produce high-quality, precision parts, which improved product consistency and reduced overall production costs.

Industrial Tools:

Application: Production of parts like gears, cutting tools, and fasteners used in industrial machinery.

Case Study: An industrial equipment manufacturer adopted MIM for producing wear-resistant gears, enhancing tool lifespan and reducing downtime in manufacturing processes.

Frequently Asked Questions (FAQs) about MIM Iron Base Alloys:

What are the typical applications of MIM iron base alloys?

MIM iron base alloys are commonly used in automotive components, medical devices, consumer electronics, aerospace parts, firearms, and industrial tools.

What are the benefits of using iron base alloys in MIM?

Iron base alloys offer high strength, good corrosion resistance, complex geometry capabilities, and cost-effective production for large volumes, making them suitable for a variety of demanding applications.

What limitations should be considered when using MIM iron base alloys?

Limitations include high initial tooling costs, size constraints, binder removal complexity, limited material selection, and potential residual porosity in parts.

What industries benefit most from MIM iron base alloys?

Industries such as automotive, aerospace, medical, consumer electronics, firearms, and industrial machinery benefit significantly from the use of MIM iron base alloys due to their mechanical properties and versatility.

How does the MIM process for iron base alloys ensure consistent quality?

The MIM process provides high repeatability, tight tolerances, and rigorous quality control, ensuring consistent part quality suitable for precision-critical industries.

Is MIM suitable for low-volume production of iron base alloys?

MIM is generally not cost-effective for low-volume production due to the high initial tooling costs. It is better suited for medium to large-scale production runs.

Can MIM iron base alloys achieve complex geometries?

Yes, MIM is ideal for producing complex geometries that are difficult or impossible to achieve through traditional manufacturing techniques, allowing for greater design freedom.

What types of iron base alloys are used in MIM?

Common iron base alloys used in MIM include 316L stainless steel, 17-4 PH, Fe-2

Finishing Options

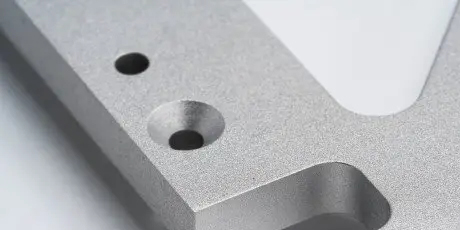

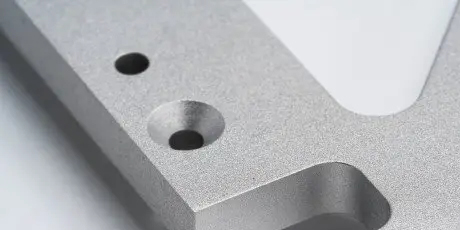

Parts Made by AutofabX