Quick Look

| Density(g/cm³) | Shore Hardness | Tensile Strength | Elongation at Break | Heat Deflection Temperature |

|---|---|---|---|---|

| 1.2 | 83-86D | 50-65MPa | 10-20% | 45℃ |

About the Material

Advantages:

Full-Color Printing: The ability to print in multiple colors and materials simultaneously, offering vibrant and realistic parts.

High Resolution: Produces parts with high resolution and smooth surface finish, suitable for presentation models and marketing samples.

Multi-Material Flexibility: Combines different material properties in a single print, allowing for varied hardness and texture.

Rapid Production: PolyJet is a fast printing method, making it ideal for creating prototypes quickly.

Limitations:

Brittleness: Multi color resin parts may be brittle, limiting their use in functional or load-bearing applications.

Material Cost: The resin used for multi-color PolyJet printing can be more expensive compared to other 3D printing materials.

Post-Processing: Parts may require additional curing and handling, which can increase the production time.

Chemical Composition Table for Multi Color Resin

| Element | Typical Composition |

| Acrylate Monomers | Varies |

| Photoinitiators | Varies |

| Color Pigments | Varies |

| Additives | Varies |

Mechanical Machining Properties Table for Multi Color Resin

| Property | Value |

| Machinability Rating | Low |

| Cutting Speed (m/min) | 10-20 |

| Tool Wear Resistance | Low |

| Coolant Requirement | Optional |

| Surface Finish Quality | High |

Design Parameters Table for PolyJet Printing with Multi Color Resin

| Maximum Bulid Size(mm) | Minimum Wall Thickness | Minimum Drill Size | Minimum Assembly Gap | Tolerance |

| 490*390*200 | 0.6mm | 0.5mm | 0.1mm | N/A |

Industry Applications and Case Studies for PolyJet Printing with Multi Color Resin

Consumer Goods:

Application: Production of product prototypes and concept models.

Case Study: A consumer electronics company used PolyJet with multi color resin to create realistic prototypes of new products, helping stakeholders visualize the final design before mass production.

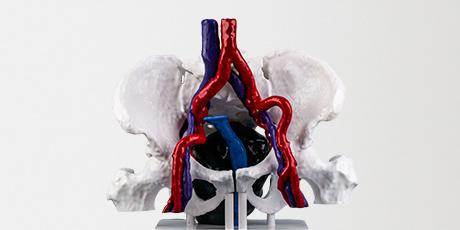

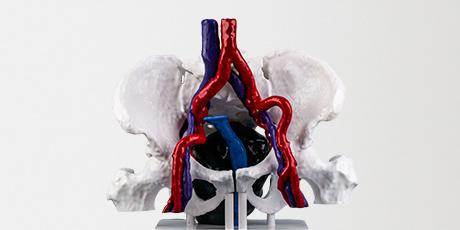

Medical Industry:

Application: Production of anatomical models for surgical planning and educational purposes.

Case Study: A medical center used PolyJet to create full-color anatomical models, providing surgeons with a better understanding of patient anatomy before complex surgeries.

Architecture:

Application: Creation of architectural models for presentations.

Case Study: An architecture firm used PolyJet printing to create detailed, multi-color models of buildings, enhancing client presentations and enabling better decision-making.

Frequently Asked Questions (FAQs) about PolyJet Printing with Multi Color Resin

What materials can be used in PolyJet printing?

PolyJet printing can use a variety of photopolymers, including rigid, flexible, transparent, and multi color resins.

Is PolyJet printing suitable for functional parts?

PolyJet is primarily used for prototyping and aesthetic models. Functional parts may require additional considerations due to the brittleness of the resin.

What industries benefit from PolyJet printing with multi color resin?

Industries such as consumer goods, medical, and architecture benefit from the high resolution, multi-color capabilities, and realistic models offered by PolyJet printing.

How accurate is PolyJet printing with multi color resin?

PolyJet printing can achieve tolerances of ±0.1 mm, making it suitable for intricate designs and detailed prototypes.

What post-processing is required for PolyJet-printed parts?

Post-processing may include support material removal, cleaning, and UV curing to achieve the desired appearance and strength.

Can PolyJet print multi-material parts?

Yes, PolyJet can print with multiple materials, allowing for varied textures, colors, and mechanical properties within a single part.

How strong are PolyJet-printed parts with multi color resin?

PolyJet-printed parts are suitable for visual models and light-duty functional prototypes but may be brittle compared to parts made with other 3D printing technologies.

Finishing Options

Parts Made by AutofabX